Icewel®

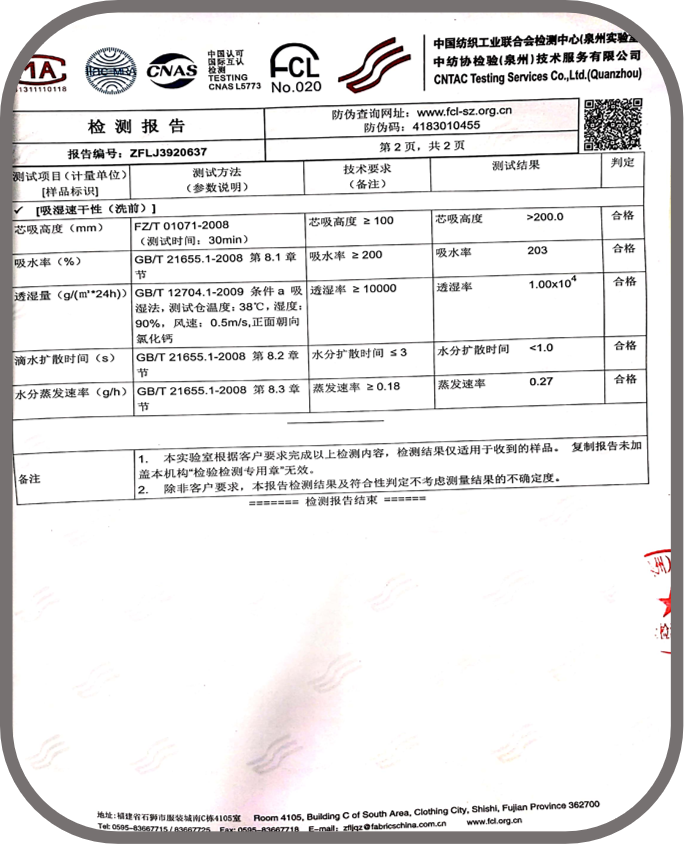

Moisture Management

Hydrophilic modification

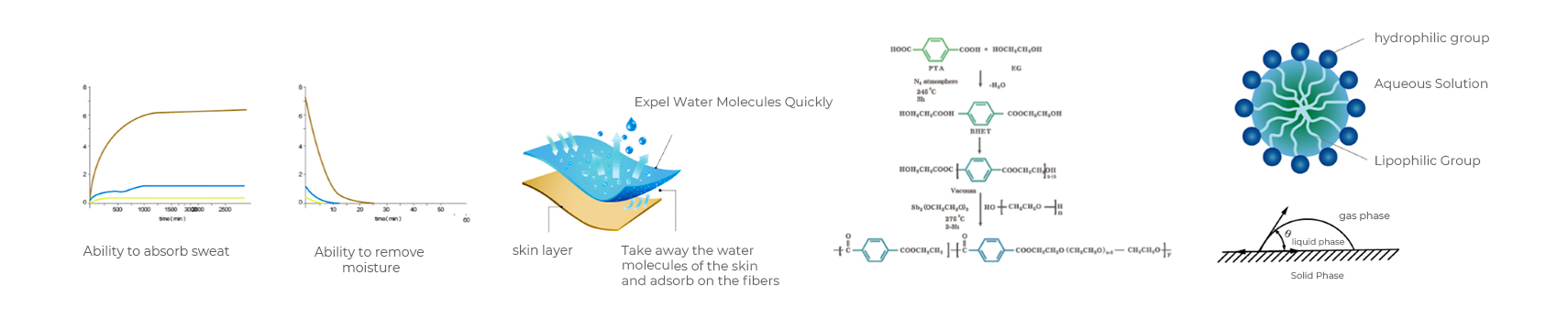

Icewel® By introducing a hydrophilic group into a conventional polyester segment, it has excellent hydrophilic properties, thereby providing the natural fiber with good hygroscopicity and comfortable wearing.

Titanium catalysis

Icewel® Adopt Titanium-based catalysts, the fibers does not contain heavy metals, and are safer and more environmentally friendly during use.

Profiled section

Icewel® has a profiled cross section that increases the fiber absorbing channel, accelerating water absorption and discharging, with significantly discharging performance.

PRODUCT TECHNICS

Polymerization

The hydrophilic group is introduced during the polymerization to increase the moisture regain of the polyester fiber

Spinning

Advanced spinning process guarantees yarn quality stability

Post processing

Special texturing process to impart a change in yarn style (elasticity, floral ash)

FEATURES

Moisture absorption and quick drying

Icewel® The fiber itself has the hydrophilic property that ordinary polyester does not have, and the moisture regain rate is increased to 2.5%. At the same time, the profiled cross section increases the fiber moisture absorption channel to accelerate the absorption and discharge of water.

Low temperature dyeable

Icewel®The dyeing rate of Icewel fabric at 95 ° C has reached 90%, which meets the requirements of atmospheric pressure dyeing;

Low temperature dyeing guarantees the color stability and color fastness of spandex elasticity, spandex and nylon.

Safety and environmental protection

Polymerization

Compared with the general Polyester, highly hydrophilic material can save 2 kg oil and 6.3MJ ingredients

Spinning

The drying temperature of hydrophilic material section is reduced by 5-10℃, and that of spinning is reduced by 5-15℃; the cycle of spinning accessories is prolonged twice.

Dyeing and finishing

Compared with the general Polyester, the dyeing temperature of hydrophilic material is lower by 5-10℃; available to boiling dyeing of 90-100℃ or conventional disperse dyethe dye-uptake of 95℃ dyeing exceeds 90%.

FIBER BRAND TAG

PRODUCT SPECIFICATIONS

APPLICATION FIELDS

Home Textile

T-shirt

Sportswear

Shirt