Polyum™

Biodegradable Fiber

What Is Polyum™ ?

Polyum™ is a chemical fiber that can be quickly biodegradable in an active microorganic environment. Its carrier is suitable for the most of chemical fibers that cannot be quickly biodegradable, such as polyester fiber, polyamide fiber (nylon).

Polyum™ can accelerate degradation in an active microorganic environment, while maintaining the original performance as a chemical fiber. In most cases, textiles made of this fiber can be completely degraded within 300 days.

Development Background

Discarded Textiles

According to statistics, over 1.4 and 11 million tons of clothes and accessories were discarded by the British and the Americans in 2021, respectively. The average American family has been estimated to throw away around 30kg of used clothes every year. In China, this figure reaches 26 million tons a year.

Harmful Incineration (Dioxin)

Such large quantities of discarded clothes are mostly dumped into landfill or burned. Waste incineration may generate dioxins, which are colorless and odorless persistent toxic pollutants and cannot be broken down easily. They can cause skin diseases, damage to the immune system, endocrine and metabolic disorder, malformation, cancer and bodily injuries. Due to those harmful effects, dioxin is listed as a Group 1 carcinogen by the WHO in 1997.

Landfill Dilemma (Lengthy Degradation)

Discarded clothes can also cause soil pollution and other environmental hazards. They are often burned, but some of them are landfilled, hence massive polyester fibers can be naturally decomposed only after 200 years.

How Does Polyum™ Achieve Biodegradability?

Why

Core Issue

Difficult to degrade and digest, without lure -Microorganisms do eat plastics, but plastic products require hundreds of years for degradation because they are neither luring, nor easy to be broken down and digested.

What

Phenomenon

Difficult to degrade – Chemical fibers can be biodegraded over hundreds of years.

Trigger

Trigger

Polyum™ may trigger biodegradability when they are put in an active microorganic environment.

How

Solution

Chemical fibers become a lure to microorganisms for quicker degradation and easier digestion.

Closed-loop System Of Polyum™:Negative Carbon Economy Solutions

Polyum™ can produce methane, carbon dioxide and small amounts of biomass and water in the process of biodegradation.

At present, recycling technologies that capture methane from landfills and convert it to renewable natural gas are being utilized by countries throughout the world.

Polyum™ enables landfills to capture methane from chemical fiber products and convert it into renewable natural gas by accelerating the rate of biodegradation of these fibers.

Masterbatch Preparation

Nano food grade nontoxic ingredients are made into masterbatch to guarantee product safety and extrusion stability.

Spinning Extrusion

Spinning Extrusion The mature and advanced blend spinning process can ensure the quality stability of spinning.

Spinning/Texturing/Post

Processing It can add with a special texturing process to endue yarns with the change of style.

Efficient Biodegradability

In most cases, Polyum TM can be completely degraded within 300 days in an active microorganic environment. The required degradation time is much shorter than that of ordinary chemical fibers.

Stable Performance

A zero-threshold condition is created in the application of downstream producers because there is no change to the physical properties or tensile strength of final products, and their weaving, dyeing and printing performance is the same as that of ordinary chemical fibers.

Universal Applicability

It can be applied to virtually any chemical fiber with product diversity and applicability, covering all textile-related industries.

Complete Degradability

Being completely degradable without the risk of partial decomposition of microplastic, it doesn’t cause secondary pollution to the environment.

Safety Added effective

ingredients of masterbatch are safe and nontoxic food grade additives.

Persistence

The use of masterbatch-added blend spinning can ensure the persistent functionality, so that the degradation function of final products will not be lost over time.

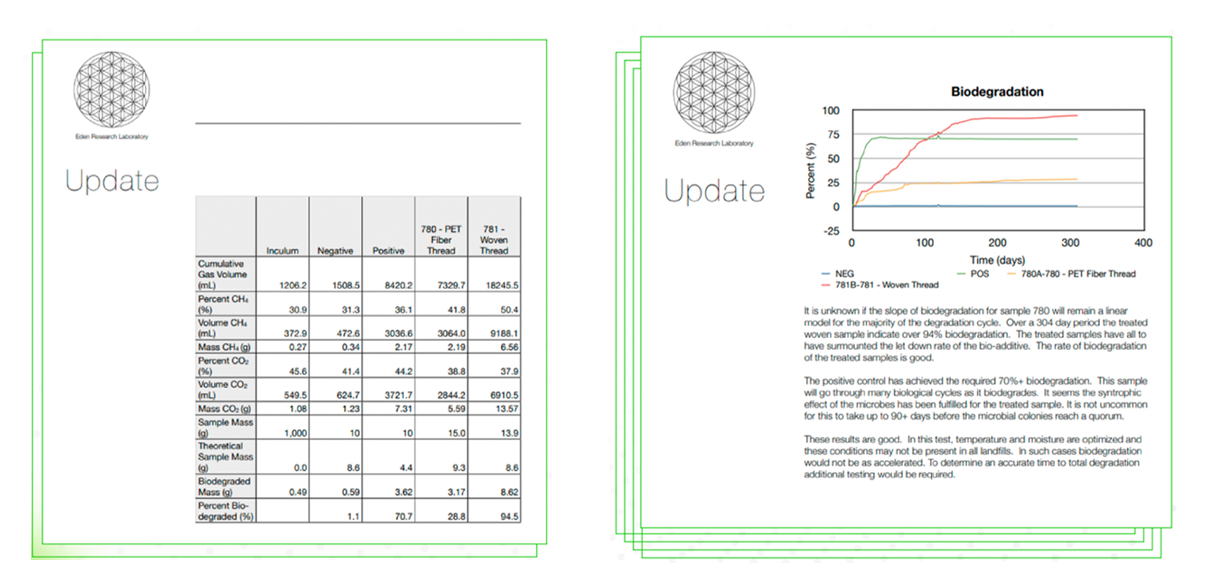

Product Test Report

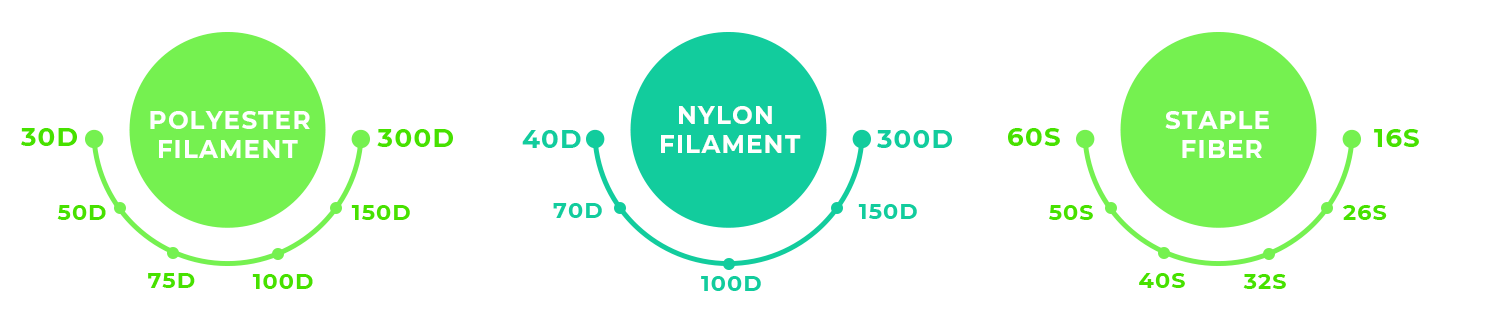

Product Specification

Product Tags